Hardening and Heating Equipment

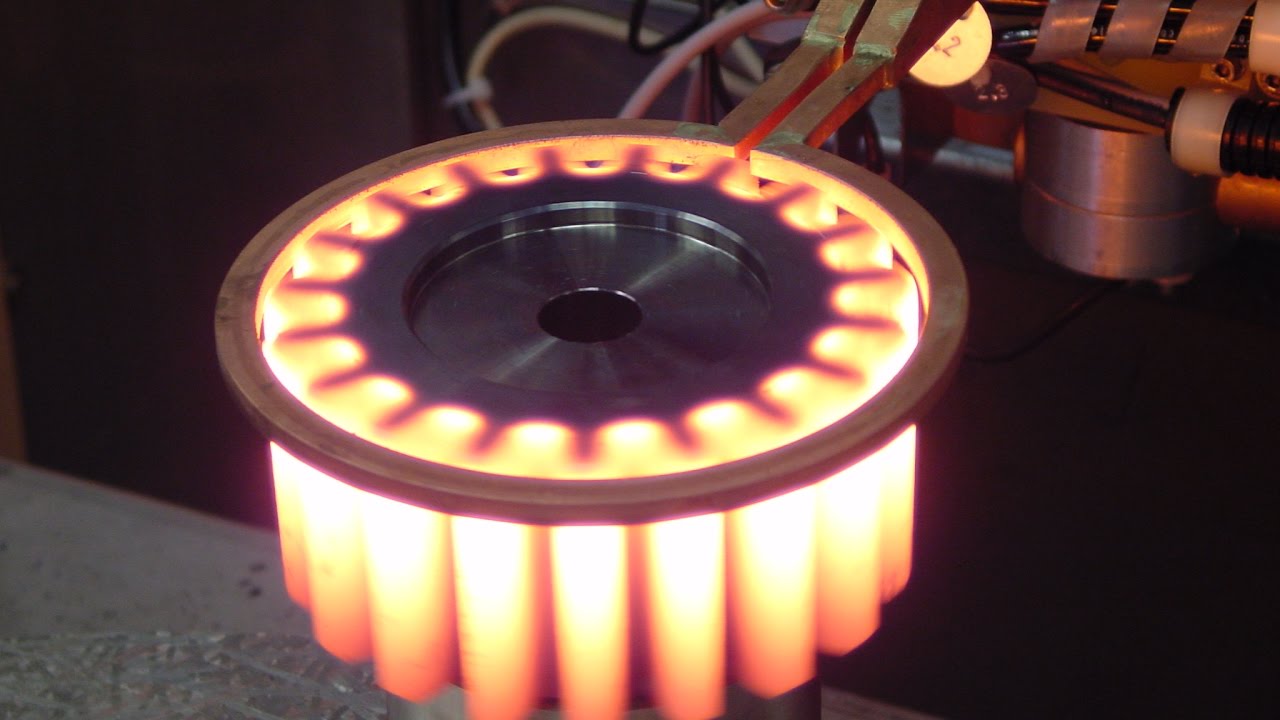

An alternative to traditional oven or furnace heating, which use convection or radiation methods for industrial applications, induction hardening and heating equipment uses electrical current rather than burning fuel to produce heat. The heat generated through induction heating and hardening involves no physical contact between the coil and the metal component that’s being heated. As a result of this method, induction heating allows for more precise control and consistent results.

At Foster Induction, we supply, install, and service top-quality induction heating and hardening equipment designed to deliver maximum efficiency for your facility. Our induction equipment uses advanced IGBT technology and high efficiency heating coils for reduced power consumption with minimal heat loss.

Customized Induction Hardening and Heating Equipment for Your Industry :

We work closely with you to determine the precise requirements of your facility, and then create a custom solution for any requirement. We supply induction heating and hardening equipment for a wide range of industries, including:

- Heat treatment and metal processing plants

- Automotive, solar, and electronics industries

- Universities, laboratories, and R&D sectors

- Aerospace and defence industries

- Forging and mining industries

Features :

- Power rating from 35 kW to 5000kW

- Material handling systems that are customized for your facility

- Compact, space-saving design to maximize your working area

- Easy-to-use controls with digital displays for improved operator interface

- Increased production rates for improved output value

- Low-loss power cables